Maritime site Russia no

The boarding of people in life-saving appliances and the launching of the latter in calm conditions should not exceed in time:

10 minutes - for cargo ships;

30 minutes - for passenger and fishing vessels.

Lifeboats and liferafts should normally be stowed on the same deck, with liferafts allowed one deck above or below the deck on which the lifeboats are installed.

A lifeboat is a lifeboat capable of saving the lives of people in distress from the moment they leave the ship.

It is this appointment that determines all the requirements for the design and supply of lifeboats.

The number of lifeboats on board a vessel is determined by the navigation area, type, vessel and the number of people on board. Cargo ships of an unlimited navigation area are equipped with boats that provide the entire crew from each side (100% + 100% = 200%). Passenger ships are equipped with lifeboats with a capacity of 50% of passengers and crew on each side (50% + 50% = 100%).

All lifeboats must:

have good stability and buoyancy even when filled with water, high maneuverability;

ensure reliable self-healing on an even keel when capsizing;

have a mechanical engine with remote control from the wheelhouse;

be dyed orange.

The lifeboat must be equipped with a compression-ignition internal combustion engine:

the engine must run for at least 5 minutes from cold start when the boat

is out of the water;

the speed of the boat in calm water with a full complement of people and equipment must be at least 6 knots; the fuel supply must be sufficient to run the engine at full speed for 24 hours.

If a ship has partially enclosed lifeboats, their davits shall be fitted with a hatchet with at least two life buoys attached to it.

The buoyancy reserve of the boat is provided by air boxes - sealed compartments filled with air or foam, the volume of which is determined taking into account that the heads of the people sitting in the boat are above the surface of the water, even if the boat is completely flooded.

Information about the capacity of the boat, as well as its main dimensions are applied to its sides in the bow with indelible paint, the name of the vessel, the port of registry (in Latin letters) and the ship's number of the boat are also indicated there. The marking by which it is possible to establish the vessel to which the boat belongs, and its number must be visible from above.

Along the perimeter of the boat, under the fender and on the deck, strips of reflective material are glued. In the bow and stern parts, crosses made of reflective material are applied on the upper part of the closure.

An electric light bulb is installed inside the boat. The battery charge ensures operation for at least 12 hours. A signal light with a manual switch is installed on the upper part of the closure, giving a constant or flashing (50-70 flashes per minute) white light.

The battery charge ensures operation for at least 12 hours.

The lifeboats for oil tankers are of fire-retardant design, equipped with a sprinkler system that allows passage through continuously burning oil for 8 minutes, and compressed air that ensures the safety of people and the operation of engines for 10 minutes.

The hulls of the boats are made double, they must have high strength, the deckhouse must provide all-round visibility, portholes made of fire-resistant glass.

To ensure the use of the boat by unqualified people (for example, passengers), instructions for starting and operating the engine should be provided in a clearly visible place near the engine controls, and the controls should be appropriately marked.

All lifeboats, liferafts, rescue boats and launching appliances are visually inspected weekly to ensure they are always ready for use.

All lifeboats and rescue boats must run for at least 3 minutes. Lifeboats, with the exception of free-fall boats, must be moved out of their stowed positions. The results of the check are recorded in the ship's log.

Every month, all lifeboats, with the exception of free-fall boats, fall out of their stowage positions without people in the lifeboat. Supplies are checked to ensure they are complete and in good condition.

Each lifeboat, with the exception of free-fall boats, is launched and then maneuvered on the water with a control command painted on it at least once every 3 months.

Boats launched by mechanical means are installed horizontally on both sides of the vessel. A davit is a device designed to store a boat, having beams that tilt overboard, used when lowering and raising the boat.

In the stowed position, the boats are mounted on davits; for this, the latter have one-sided keel blocks on which the boat rests. For a tighter fit of the boat to the keel blocks, the latter are equipped with a felt cushion covered with canvas. The boat is secured with lashings with a verb-hook, which must be given before launching.

Before launching the boat, you must first:

deliver to the boat the equipment and supplies necessary for survival after leaving the ship:

a portable VHF radio and radar beacon, warm clothes, an additional supply of food and water, an additional supply of pyrotechnic signaling equipment;

remove the railing of the landing deck;

prepare a storm ladder;

give lashings;

give stopper davits.

The lifeboat must be equipped with a drain valve, which is installed at the bottom of the bottom of the lifeboat to drain water. The valve automatically opens when the boat is out of the water and closes automatically when the boat is afloat. When preparing the boat for launching, the valve must be closed with a cap or plug.

The dumping of the boat occurs only under the action of gravity and is carried out with the help of boat hoists. Before the start of the descent, the stopper on the davits is released and the fall of the hoists is smoothly eased, for which the brake of the boat winch is gradually released. Uniform etching of the bow and stern hoists is achieved by the fact that both falls are fixed on the drum of one boat winch. After the davit reaches the limit position, the vertical descent of the boat into the water begins.

Lapps are steel cables attached to the boat at its extremities and carried to the winch, designed to lower and raise the boat. Lopari should be periodically tired.

In order to exclude the possibility of launching the boat until it is completely thrown overboard, there is a horn on the davit, on which the earring of the movable block of davits is hung.

The length and shape of the horn is chosen in such a way that the movable block falls off it only at the lower limit position of the davit.

The launching of the boat on hoists can be controlled both from the deck of the vessel and from the boat. This makes it possible, under favorable weather conditions, not to leave the descent support team on board. After the boat is launched into the water, the lower blocks of the sloops are laid out.

It is very important, especially in waves, to lay out both blocks at the same time. For this, the boats have folding hooks with a common drive. In this case, the simultaneous return of both hooks is carried out by turning the drive handle.

1 - davit; 2 - Lapp; 3 - sloops; 4 - painter.

Landing of people is carried out on storm ladders

Landing of people is carried out on storm ladders

Each boat in the area of its installation has a landing ladder, the strings of which are made of a manila cable with a thickness of at least 65 mm, and the balusters are made of hardwood with a size of 480x115x25 mm.

The upper end of the ladder must be fixed in its regular place (under the boat), and the ladder itself must be rolled up, always ready for use.

After the last person moves from the ship to the boat, the painters are released (in extreme cases, they are cut with axes located at the ends of the boat), and the boat moves away from the ship. It is recommended to keep the fallini, because. they may still be needed.

Boat supply

Boat supply

Each lifeboat must be equipped in accordance with the requirements of the International Convention SOLAS-74, including:

on rowing boats, one floating oar per rower plus two spare and one helmsman, on motor boats - four oars with oarlocks attached to the boat hull with pins (chains);

two rebate hooks;

floating anchor with a cable length equal to three lengths of the boat, and a guy attached to the top of the anchor cone;

two painters with a length of at least 15 meters;

two axes, one at each end of the boat for cutting painters when leaving the ship;

food ration and supply of drinking water 3 liters for each;

stainless ladle with shtert and stainless graduated vessel;

fishing equipment.

Signal means:

four red parachute rockets, six red flares, two smoke bombs,

electric lantern with Morse code signaling device in a waterproof design (with a set of spare batteries and a spare bulb),

one signal mirror,

Heliograph - with instructions for its use, signal whistle or equivalent signal device, tables of rescue signals;

floodlight capable of continuous operation for 3 hours;

first aid kit, 6 seasickness tablets and one hygiene bag per person;

a folding knife attached to the lifeboat with a pin and three can openers;

hand drain pump, two buckets and scoop;

fire extinguisher for extinguishing burning oil;

a set of spare parts and tools for the engine;

radar reflector or SART;

binnacle with compass;

individual heat protective equipment in the amount of 10% of the passenger capacity of the boat (but not less than two).

Free fall boats

Free fall boats

The hull of the boat has a stronger structure and well-streamlined smooth lines that prevent a strong impact when the boat enters the water. Since overloads occur when hitting water, special chairs with shock-absorbing pads are installed in the boat.

Before the boat leaves the ramp, the crew must securely fasten themselves with seat belts and a special head restraint. Free fall boats guarantee the safety of people when falling from a height of up to 20 meters.

Free-fall boats are considered the most reliable life-saving equipment that ensures the evacuation of people from a sinking ship in all weather conditions.

This is a type of lifeboat designed to rescue people from the water (those who have fallen overboard or found at sea) and to collect lifeboats and rafts.

The advantage of a rescue boat is the speed and reliability of launching and recovering on board on the move in light seas. A powerful stationary or outboard motor allows you to quickly examine the area where a person has fallen overboard, pick him up and deliver him to the ship.

The rescue boat is capable of performing rescue operations in stormy conditions and with limited visibility. The rescue boats are in constant readiness. Preparation and descent of the boat are made in 5 minutes.

The boat has a place for transporting the rescued person in the supine position. Engine power provides a speed of at least 8 knots, and the fuel supply is enough for 3 hours of full speed. The propeller is protected to prevent injury to people at sea.

Rescue equipment is a set of tools for rescuing people from a sinking ship or if they fall overboard. It includes life-saving appliances and devices for their installation, attachment to the vessel and launching. It can be collective (boats, rafts, life tables) and individual (life buoys, bibs, vests) use.

A davit is a device for launching a boat from a ship into the water and lifting it aboard. Each boat is served by two davits. The combination of a boat, a keel block, as well as deck lifting mechanisms for lifting and lowering the boat into the water constitutes a boat device.

Each davit consists of a boom, a supporting structure, a boat hoist (davit) and a mechanism that provides movement, such as a winch.

Davits can be: horizontal, overturning and rotary.

Davits are divided into 3 types: horizontal, overturning and rotary.

Horizontal(tilting, gravitational, rolling or articulated) davits fall out under the influence of the mass, their own and the boat, after the return of the lashings, marching stop and winch band brake. The advantage of this design is that the boats can be stored on high decks and far from the side; the disadvantage is that in winter, due to freezing of the guide beds, before launching the boat into the water, it may be necessary to chip off ice from them.

Design collapsing(folding) of the davit provides for falling out and filling up with special screw and gear devices. Often davits of this design are used on small ships and ships. The disadvantage of all, except for the sickle-shaped, falling davits, is that the distance between their pair must exceed the length of the boat they serve, which inevitably leads to irrational use of the boat deck area.

Collective ship's life-saving appliances (CSS) are the means that can be used by a group of people.

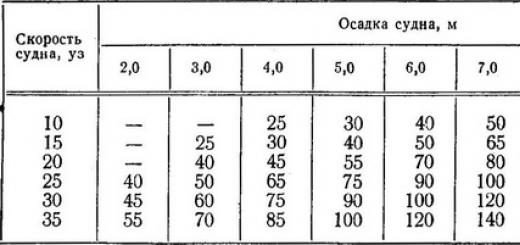

Collective SSS and their launching devices must ensure reliable and safe operation so that they can be launched at the smallest draft of the vessel with a list of 20 ° on any side and a trim of 10 °.

The boarding of people in life-saving appliances and the launching of the latter in calm conditions should not exceed in time: 10 minutes - for cargo ships; 30 minutes - for passenger and fishing vessels of an unlimited navigation area.

Lifeboats and liferafts should normally be stowed on the same deck, with liferafts allowed one deck above or below the deck on which the lifeboats are installed.

LIFEBOATS.

Lifeboat - this is a lifeboat capable of saving the lives of people in distress from the moment they leave the ship. It is this appointment that determines all the requirements for the design and supply of lifeboats.

According to the method of delivery to the water, lifeboats are divided into mechanically launched and free-fall launched.

The number of lifeboats on board a vessel is determined by the navigation area, type, vessel and the number of people on board. Cargo ships of an unlimited navigation area are equipped with boats that provide the entire crew from each side (100% + 100% = 200%). Passenger ships are equipped with lifeboats with a capacity of 50% of passengers and crew on each side (50% + 50% = 100%).

Regardless of design differences, all lifeboats must: have good stability and buoyancy even when filled with water, high maneuverability; ensure reliable self-healing on an even keel when capsizing; have a mechanical engine with remote control from the deckhouse, ensuring the speed of the boat in calm water with a full complement of people of at least 6 knots and a propeller protected from accidental impacts; be dyed orange.

Along the perimeter of the boat, under the fender and on the deck, strips of reflective material are glued. In the bow and stern parts, crosses made of reflective material are applied on the upper part of the closure.

Fig.73. Lifeboat closed type.

Lifeboats for oil tankers have a fireproof design, equipped with systems: irrigation, providing passage through continuously burning oil for 8 minutes; compressed air, ensuring the safety of people and the operation of engines for 10 minutes. Boat hulls are made double, they must have high strength; the cabin should provide all-round visibility, portholes are made of fire-resistant glass.

The lifeboat must be equipped with a compression-ignition internal combustion engine: the engine must run for at least 5 minutes from the moment of cold start, when the lifeboat is out of the water;

The speed of the boat in calm water with a full complement of people and equipment must be at least 6 knots; the fuel supply must be sufficient to run the engine at full speed for 24 hours.

Fig.74. Lifeboat open type.

Fig.74. Lifeboat open type.

To ensure the possibility of using the boat by unqualified people (for example, passengers), in a clearly visible place near the engine controls, instructions for starting and operating the engine should be provided, the controls should be appropriately marked.

If a ship has partially enclosed lifeboats, their davits shall be fitted with a hatchet with at least two life buoys attached to it.

Toprik - a cable stretched between the ends of the davits.

Rescue pendant - a vegetable or synthetic rope with musings (knots) used as an emergency means for launching from a vessel into a boat or into the water.

Information about the capacity of the boat, as well as its main dimensions, are applied to its sides in the bow with indelible paint; the name of the ship, the port of registry (in Latin letters) and the ship's boat number are also indicated there. The marking by which it is possible to establish the vessel to which the boat belongs, and its number must be visible from above.

Fig.75. Lifeboat marking.

The boat must either be self-draining or have a hand pump to remove the water.

The lifeboat must be equipped drain valve. A drain valve (one or two depending on the size of the boat) is installed at the bottom of the bottom of the boat to release water. The valve automatically opens when the boat is out of the water and closes automatically when the boat is afloat. Usually this task is performed by a float type valve. When the boat is stored on board, the drain valve must be open to allow any water that has entered the boat to drain. When preparing the boat for launching, the valve must be closed with a cap or plug.

Boats lowered on hoists are equipped with a release mechanism, which is designed in such a way that both hooks are released simultaneously. In this case, the uncoupling mechanism provides for two ways of uncoupling: normal - uncoupling occurs after the boat is launched into the water, when the load on the hooks disappears; under load - when disengagement can be carried out both on the water and on weight in the presence of a load on the hooks.

A signal light with a manual switch is installed on the upper part of the closure, giving a constant or flashing (50-70 flashes per minute) white light. The battery charge ensures operation for at least 12 hours.

Lifeboats with an independent air supply system must be designed so as to ensure normal engine operation for at least 10 minutes with closed entrances and openings. At the same time, the air must remain safe and breathable.

Fig.76. Disconnect devices.

Fireproof lifeboats must ensure the safety of the people in them for at least 8 minutes, being on the water in the zone of fire covering it from all sides, and the air temperature at the level of the head of a sitting person should not exceed 60 ° C. Typically, such boats are equipped with a water spray system to increase fire resistance. Outboard water is used for irrigation. The water intake device of the system is located in the lower part of the boat in such a way as to prevent flammable liquids from entering the system from the surface of the water.

Boat supplies.

Each lifeboat must be equipped in accordance with the requirements of the SOLAS-74 International Convention, including: on rowing boats, one floating oar per rower plus two spare and one helmsman, on motor boats - four oars with oarlocks attached to the boat hull with pins (chains); two rebate hooks; floating anchor with a cable length equal to three lengths of the boat, and a guy attached to the top of the anchor cone; two painters with a length of at least 15 meters; two axes, one at each end of the boat for cutting painters when leaving the ship; food ration and supply of drinking water 3 liters for each; fishing equipment; signal means: four red parachute rockets, six red flares, two smoke bombs, an electric flashlight with a Morse code signaling device in a waterproof design (with a set of spare batteries and a spare light bulb), one signal mirror - heliograph - with instructions for its use , signal whistle or equivalent signal device, tables of life-saving signals;

Fig.77. Parachute rocket.

Floodlight capable of continuous operation for 3 hours; first aid kit, 6 seasickness tablets and one hygiene bag per person; a folding knife attached to the lifeboat with a pin and three can openers; hand drain pump, two buckets and scoop; fire extinguisher for extinguishing burning oil; a set of spare parts and tools for the engine (on motor boats); radar reflector; binnacle with compass; individual heat-protective means in the amount of 10% of the passenger capacity of the boat (but not less than two).

Once a month, boat equipment should be checked, ventilated and dried.

Fig.78. Boat supplies.

Launching the boat.

Boats launched by mechanical means are installed horizontally on both sides of the vessel. Davits are a device designed to store a boat, having beams that tilt overboard, used when lowering and raising the boat.

The descent of the boat is carried out on the falls along the side of the vessel until the boat is on the water.

Lopari - steel cables attached to the boat at its ends and carried to the winch, designed to lower and raise the boat.

The launch of the boat occurs only under the action of gravity or accumulated mechanical energy and does not depend on the ship's energy sources.

The launching of a hoisted boat can be controlled both from the deck of the vessel and from the boat. This allows, under favorable weather conditions, not to leave the descent support team on board.

A feature of the most common gravity davits is the falling out of the boat under the action of gravity after the recoil of the stoppers. They are distinguished by the speed of falling out - no more than 2 minutes, reliable operation with a roll of up to 20 °.

Fig.79. Lifeboat anchorage on board.

Gravity davits are divided into rolling (sliding) ones, in which the boom with a lifeboat suspended from it moves along the bed guides on rollers, while dumping the lifeboat, and hinged ones, which force the lifeboat out by turning around the hinge located at the lower end of the davit.

Each pair of davits is served by one boat winch with a manual or mechanical drive.

Each boat in the area of its installation has a landing ladder, the bowstrings of which are made of a manila cable with a thickness of at least 65 mm, and the balusters are made of hardwood with a size of 480x115x25 mm.

The upper end of the ladder should be fixed in its regular place (under the boat), and the ladder itself should be rolled up, always ready for use.

Fig.80. Boat winch.

Fig.81. Stormtrap.

Before launching the boat into the water, you must perform a number of actions:

1) Delivery to the boat of equipment and supplies necessary for survival after leaving the ship:

Portable VHF radio and radar transponder beacon (SART);

Fig.82. Radar beacon transponder (SART) and portable VHF radios.

Warm clothes (blankets);

Additional supply of food and water;

Additional supply of pyrotechnic signaling means.

2) Before launching, it is necessary to close the drain valve with a plug (located at the lower point of the hull and has the appropriate marking).

3) If necessary, prepare for the use of painters from emergency supplies, which are attached to the ends of the boat and carried along the side. A boat lowered on falls along the side in stormy conditions must be kept from swinging and beating against the side of the vessel. If the boat is launched when the vessel is moving through the water, then in this case it is also necessary to use a painter to hold the boat at the side.

When lowering the boat, the painters are etched into tight through ducks or other suitable structural elements. If the length of the painter allows, then it is preferable to wind it up with a duline (wiring around some structural element and returning the running end to the boat) so as not to leave people on board the vessel who would then have to go down into the boat along the ladder.

4) Removing the railing of the landing deck.

5) Preparation of the ladder.

6) Return of lashings.

7) Recoil of the davit stopper.

Fig.83. Boarding the crew and launching the boat.

Boarding of people in a hoisted boat can be carried out: on passenger ships - either at the place of its installation, or from the landing deck; on cargo ships - at the place of installation.

Further control of the descent is carried out using the hand brake of the trigger winch. The brake is released, and the boat, under the influence of its own gravity, begins to dump the davit overboard and sink. When boarding passengers from the landing deck, the descent is slowed down by bringing the boat inlet to the level of the landing deck.

After landing people in the boat, the hand brake is released, and the boat is lowered into the water.

Disengagement from the falls should be done at the moment when the boat is at the bottom of the wave: after passing this position, the boat will begin to rise to the crest, and there will be no load on the hooks.

The fallini are fastened in such a way that the boat is at the side under the ladder. After the last person moves from the ship to the boat, the painters are released (in extreme cases, they are cut with axes located at the ends of the boat), and the boat moves away from the ship. It is recommended to save the fallini, because they may be needed for towing, for combining with other life-saving appliances, for pulling the boat ashore, etc.

Fig.84. Return of sluptals.

In recent years, life-saving free fall boats. The hull of the boat has a stronger structure and well-streamlined smooth lines that prevent a strong impact when the boat enters the water. Since overloads occur when hitting water, special chairs with shock-absorbing pads are installed in the boat.

Fig.85. Free fall boat.

Before leaving the boat ramp, all people in the boat must securely fasten themselves with safety belts with a quick-release buckle and a special head lock. Of great importance for the safe perception of dynamic loads is the correct position of the body in the chair, which should be practiced in training - during training boat alarms.

Free fall boats guarantee the safety of people at a distance of 20 m from the landing platform to the water surface.

Free-fall boats are considered the most reliable life-saving equipment that ensures the evacuation of people from a sinking ship in all weather conditions.

Hull design

There are a number of requirements for hull design, some of which are listed below:

1) All lifeboats must be of sufficient strength to:

· they can be safely launched when loaded with their full complement of men and equipment; and

· they could be launched and towed at the forward speed of the vessel at a speed of 5 knots in calm water.

2) The hull of the lifeboat must be rigid, of non-combustible or non-combustible material.

3) The boat must have a closure on top that protects people from the effects of the external environment:

If the closure is completely rigid, then such a boat is closed type boat.

If part of the closure is a soft canopy, then such a boat is a partially enclosed boat. At the same time, the bow and stern ends must be protected by at least 20% of the length with rigid closing elements. The awning is usually made of two layers of waterproof fabric with an air gap. In the open state, the awning is twisted and fixed over the entrance.

Passenger ships can be completed with boats of both types, and cargo ships - only with closed type boats (SOLAS-74 Chapter III rules 21 and 31).

The placement of boats of a partially closed type on passenger ships gives a great advantage in the speed of boarding passengers during evacuation.

4) Lifeboats must have a reserve of buoyancy that allows a fully flooded lifeboat with supplies and people in it to be kept afloat.

This additional buoyancy is provided by lightweight buoyancy materials that are resistant to sea water and oil products. These buoyancy elements are usually located along the inner perimeter of the boat under the seats.

5) Lifeboats must be stable when they are filled with 50% of the number of people allowed to be accommodated, sitting in a normal position on one side of its centreline.

6) Enclosed lifeboats must be self-recovering when capsized.

Capsizing can occur, for example, under the impact of a collapsing wave crest, which is most likely when the boat enters the zone of wave deformation in shallow water.

Boat equipment

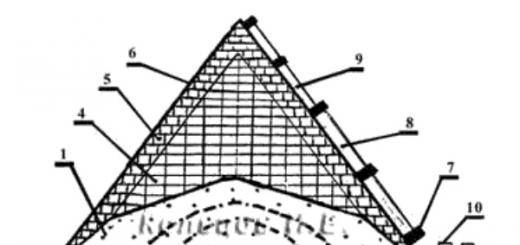

Scheme of the device of a fireproof lifeboat launched on the falls

Seating places.

Seats are equipped on transverse and longitudinal banks or fixed seats. The way the seats are equipped is usually related to the type of boat.

| The layout of the seats in the boat, launched on the falls In a boat launched on falls, most of the seats are equipped on banks located along the sides (with their backs to the side). On boats of large capacity, when the width allows, additional places can be equipped on the longitudinal banks in the middle (facing the side), or on the transverse banks. |

| The layout of the seats in the lifeboat, launched by free fall In boats launched by free fall, seats with backs and head restraints are installed. They are installed in transverse rows so that people sit facing the stern, which ensures that the inertia of a person is accepted by the back when the boat enters the water. |

Fully enclosed boats require the seats to be equipped with seat belts.

Engine

Every lifeboat must be equipped with an internal combustion engine. Lifeboats shall be equipped with compression ignition engines meeting the following requirements:

1) The engine is capable of running for at least 5 minutes from the moment of cold start, when the boat is out of the water.

This allows you to start the engine for periodic checks out of the water, and in the event of leaving the vessel, lower the boat into the water with the engine already running and immediately move away from the vessel.

2) The speed of the boat in calm water with a full complement of people and equipment must be at least 6 knots, and not less than 2 knots when towing the largest capacity liferaft installed on this vessel, loaded with a full complement of people and equipment.

3) The fuel supply must be sufficient to run the engine at full speed for 24 hours.

To ensure that the boat can be used by unqualified people (for example, passengers), instructions for starting and operating the engine should be provided in a clearly visible place near the engine controls, and the controls should be appropriately marked (Appendix 4).

dehumidification

1) The boat must either be self-draining or have a hand pump to remove water.

2) The lifeboat must be equipped with a bleed valve.

Bleed valve(one or two depending on the size of the boat) is installed at the bottom of the bottom of the boat to lower the water. The valve automatically opens when the boat is out of the water and closes automatically when the boat is afloat. Usually this task is performed by a float type valve.

Each bleed valve is provided with a cap or stopper attached by a pin or chain next to the valve to close it.

When the boat is stored on board, the drain valve must be open to allow any water that has entered the boat to drain.

When preparing the boat for launching, the valve must be closed with a cap or plug.

Boat access

Entrances to the lifeboat are made from both sides and are of such dimensions and position that it is possible to lift people in a helpless state on board the lifeboats, both from the water and on a stretcher.

The lifeboat is designed and located in such a way that all people assigned to the lifeboat can board it:

on a passenger ship - within no more than 10 minutes after the command to board is given; on a cargo ship - within no more than 3 minutes after the command to board is given.

The lifeboat must have a boarding ladder that allows people to climb into the lifeboat from the water. As a rule, the gangway is made removable and stored inside the boat.

On the outside, along the sides of the boat above the waterline (within reach for a person in the water), a handrail or lifeline is installed.

If the boat is not self-recovering, then the same handrails should be installed in the lower part of the hull so that people can hold on to the capsized boat.

If a ship has partially enclosed lifeboats, their davits shall be fitted with a hatchet with at least two life buoys attached to it.

Toprik- a cable stretched between the ends of the davits.

Rescue pendant- a vegetable or synthetic rope with musings (knots) used as an emergency means for launching from a vessel into a boat or into the water.

signal fire

A signal light with a manual switch is installed on the upper part of the closure, giving a constant or flashing (50-70 flashes per minute) white light. The battery charge ensures operation for at least 12 hours.

Emergency lighting

Inside the boat, a light source is installed in the upper part, providing sufficient illumination for reading instructions. The battery charge ensures operation for at least 12 hours.

Navigation has been and remains one of the activities associated with the risk to human life. Statistical reports of international maritime insurance companies and rescue services clearly show that the number of shipwrecks of marine transport vessels remains at a fairly high level. Every year, about 1.5% of the total number of ships in the world fleet is involved in disasters. And this is despite the constantly improving design of ships, increasing the reliability of their engines, equipping the fleet with the most advanced means of navigation and providing ships in the ocean with constant facsimile meteorological information.

According to the English Lloyd's Insurance Society, 1978 was a record year for accidents in the entire history of navigation: then 473 ships were lost (with a total gross tonnage of 1,711,000 registered tons) and about 2,000 people were on them. The main reasons for the loss of ships were severe weather conditions at sea (169 accidents) and miscalculations in navigation - grounding, underwater rocks, etc. (144 ships). The large number of casualties can be partly explained by the imperfection of the life-saving equipment possessed by the crews of the wrecked ships. Even if the survivors managed to get into the boats, many of them did not wait for help - they died from hypothermia, hunger or thirst.

The history of navigation shows that shipbuilders were forced to seriously engage in intensive development of ship's life-saving equipment only after the death of ships, which were distinguished by a particularly large number of victims. The beginning was laid by the adoption of a series of design requirements for lifeboats, developed at the International Conference on the Safety of Life at Sea in 1914, held after the loss of the Titanic. As a result of the experience of two world wars, when a huge number of transport ships and sailors died, inflatable life rafts appeared. With the development of the transportation of petroleum products and the increasing incidence of accidents with tankers, which are often accompanied by fires of spilled oil in the sea, special designs of fire-resistant lifeboats, etc., have been developed.

Now, on the davits of modern ships, it is almost impossible to find lifeboats of the first generation - with a wooden hull, air boxes made of thin metal, boats in which the survivors were open to the tropical sun and downpours penetrating the bones of the north winds. In the 1950s and 1970s, they were replaced by boats made of light non-corrosive aluminum alloys or fiberglass, equipped with a manual mechanical propeller drive or a diesel engine and a folding awning made of waterproof fabric, providing elementary protection of people from the external environment. The reserve of emergency buoyancy began to be placed in the compartments that make up part of the hull structure; on plastic boats, foam was used for this purpose. During these years, the designers of marine boats worked to improve their stability, unsinkability and reliability in various navigation conditions - from the Arctic to the tropics, to ensure the possibility of their use in a semi-submerged position, and to improve the starting qualities of engines in extreme conditions.

And yet, the design of the boats of the 70s did not always ensure the survival of the people who trusted them with their lives. Fabric awnings could not create sufficient thermal protection from the external environment; they were often damaged by waves and storm winds. There were cases of capsizing boats by a wave when people found themselves in cold water. And although the boats were supplied with devices for straightening them into a normal position, in most cases it was not possible for exhausted people to do this. It is no coincidence that our shipbuilders already in those years began work on the creation of boats of a closed type - with a rigid superstructure and capable of returning to their normal position, being overturned, on their own without the help of people.

Two such boats "ZSA22" and "ATZO" were equipped with ballast tanks located in the bottom of the hull and filled with water by gravity when the boats were launched into the water. In the position of the keel turned upside down, the water ballast turned out to be at the very top, the boat became unstable and, with a slight impact of the wave, quickly returned to its normal position. However, due to the constant presence of ballast water in the tank, the displacement of the boats turned out to be significant, which required an increase in diesel power in order to reach the minimum speed regulated by the rules of 6 knots. And this turned into an additional weight of the engine, an increase in the volume it occupied. It was necessary to continue the search for a more effective way of self-healing.

In the early 1970s, the Maritime Intergovernmental Organization (IMO) appealed to the governments of IMO member countries with an urgent appeal to intensify the activities of scientific and industrial organizations in solving the problem of ensuring the safety of navigation. The IMO Subcommittee on Life-Saving Appliances revised the content of Chapter III "Life-Saving Appliances" of the International Convention for the Safety of Life at Sea, 1974 (SOLAS-74). The work, in which specialists from the Soviet Union also participated, was completed in 1983 and the new requirements for life-saving equipment will come into force on July 1, 1986. the next, new generation, and by 1991 the old boats should be replaced on ships built earlier.

SOLAS-74 provides for the creation of lifeboats with the maximum possible satisfaction of the requirements at the level of development of modern technology, ensuring their effectiveness in rescuing seafarers in distress. Briefly, these requirements are as follows.

In the event of capsizing with the keel up, the boat must return to its normal position on its own. The crew should have no difficulty in disengaging the lifeboat from the ship's life-saving appliances when it is hung on the hooks above the water or, after being launched, is towed at a speed of 5 knots. The design of the lifeboat must ensure the reception of the injured on stretchers, the lifting of exhausted people from the water, the safe movement of people outside the lifeboat and their removal from the board using helicopters. The lifeboat must reach a speed of at least 6 knots when fully laden with persons and supplies and sailing with all auxiliary machinery powered by the main engine in operation. The engine must be able to start while the boat is still on the davits and run for at least 5 minutes before it touches the water. If water enters the boat, the engine must run until the water reaches the level of the crankshaft. The propeller must be reliably protected from damage by floating debris; the possibility of injury to people floating near the propeller must be excluded.

These and many other requirements of SOLAS-74 are not far-fetched, they follow from the generalization of many years of experience in the use of life-saving equipment and the capabilities of modern technology.

Since the beginning of the 1980s, work has begun in our country to create a new generation of lifeboats that meet the requirements of SOLAS-74 and are designed to replace mass-produced aluminum and plastic boats supplied to ships in the previous 15-20 years. This required, when designing, to keep within the allowed (rather narrow) limits the main dimensions, capacity, empty weight of the boats, the distance between the hooks of the lifting device in accordance with the data of the boats being replaced, so that it would not be necessary to modernize ships already in operation. It was decided to abandon the use of manual propeller drives as ineffective in saving people.

In a relatively short time, prototypes of boats of several standard sizes were designed and built, their extensive interdepartmental tests were carried out, and technical documentation for serial production was prepared.

The prototype of the fireproof lifeboat project "00305" for tankers was the first to be tested. According to the requirements of SOLAS-74, the design of such a boat must ensure the protection of people inside it from smoke and fire when passing through the zone of burning petroleum products for at least 8 minutes. The hull of the boat was made of aluminum-magnesium alloy.

The boat can descend from the side of the emergency vessel directly into oil products burning on the water. Its bottom, sides, decked part, closing walls and deckhouse are protected from flame by a special mastic that can withstand high temperatures for 2 minutes. This is done using a compressed air system supplied from cylinders, the capacity of which ensures the operation of the engine and the breathing of people in the boat for at least 10 minutes.

As soon as the boat is launched, the water protection system begins to operate. Outboard water enters through the kingston, located in the bottom of the boat, and is supplied by a centrifugal pump, driven from the main engine through a multiplier (increasing the engine crankshaft speed to the speed required by the pump characteristic) to the side and deck pipelines. Through the sprayers installed on the pipelines, water irrigates the surfaces of the boat, creating a continuous water film that protects the aluminum hull from direct contact with the flame.

During the tests, the boat passed through a zone of burning oil products with a temperature of 1000-1100 ° C; at the same time, the temperature inside the boat did not exceed 47 ° C, and the content of carbon monoxide and carbon dioxide in the air did not exceed the permissible limits.

The boat was accepted in 1982 by the interdepartmental commission and became the first domestic boat that meets the requirements of SOLAS-74. Its creators were awarded in 1983 with VDNKh medals.

You can get acquainted with the main design features of the new generation boats on the example of a plastic boat with a capacity of 66 people of the project "00036". Her prototype passed interdepartmental tests in 1985 (see color drawing).

The boat has a characteristic superstructure, the shape and dimensions of which play an important role in ensuring the ability of the boat to return to a straight position after capsizing. The volume of the superstructure, or rigid closure, as it is called by specialists (inherited from old boats with fabric awnings!), Must be large enough so that in the capsized state the center of gravity of the boat rises high enough, and the cross-sectional shape of the part of the hull that is under water approaches to bypass the barrel - this is the key to successful self-healing. And so that in an overturned state people do not fall on the ceiling of the closure, for each of the rescued, seat belts are provided for fastening to the seats.

In the aft part of the superstructure there is a small wheelhouse for the helmsman with a separate hatch that allows you to steer the boat, leaning out to the shoulders. For landing people, wide hatches are provided, and the bow hatches serve to lift people out of the water and receive stretchers with victims. In the same hatches, in the event of an engine failure, rowers with oars can be located. On the roof of the superstructure along its entire length, a railing is installed for the safe movement of people; here you can also install a removable folding mast for mounting a beam antenna of a portable boat radio station, as well as a passive radar reflector. On both sides, a lifeline is attached to the fender, by which people floating near the boat can be held. The propeller is protected by an annular guard.

Now let's look inside the "hard closure", where 66 fleeing people can be located well protected from splashes and cold. All of them can be placed on longitudinal and partially on transverse banks. Food rations, canned drinking water and part of the boat's supplies are stored under the banks.

An engine is installed in the stern of the boat - a diesel engine "4CHSP 8.5 / 11-5 Caspiy-30M", developing 34 hp. at 1900 rpm of the crankshaft. It is equipped with a manual start and an electric starter and works on the propeller shaft through a reverse gear transmission of the RRP-15-2 type. The engine can be started manually at an ambient temperature of up to -15 ° C. It is cooled by outboard water, but is able to operate for 5 minutes when the boat is still on the davits, and remains operational even in the inverted position of the boat.

The speed of the boat at full displacement and with all working mechanisms attached to the engine is 6.3 knots. The fuel reserve ensures the operation of the engine for 24 hours.

In the event of a capsizing of the boat, its hatches and all pipelines and devices going outside are sealed. The necessary amount of air to ensure the operation of the engine and the breathing of people enters the boat through two ventilation heads, equipped with a ball device that blocks their openings in an overturned state. The exhaust pipeline and vent pipes of fuel tanks are equipped with the same shut-off "automatic" device.

A generator mounted on the engine and batteries feed a two-wire DC network with a voltage of 24 V. Consumers of electricity are lamps for the interior lighting of the boat and a searchlight. In the daytime, lighting is provided through portholes installed on the hard closing and in the wheelhouse.

The boat is equipped with a launching device consisting of two folding hooks, the design of which meets the requirements of SOLAS-74; the helmsman can release both hooks remotely without leaving his post, or each hook can be released from the sloop-hoists separately. The hooks are fixed on steel posts, the passages of which through the deck are made watertight.

The hull of the described boat is made of fiberglass, the starting materials for which are polyester resin, fiberglass and fiberglass. The hull has a three-layer construction - the space between the inner and outer skin is filled with polyurethane foam. The outer skin is reinforced with "inflatable" tubular frames, which are filled with polyurethane foam.

Polyurethane foam provides emergency buoyancy of the boat in case of a hole in its bottom. With such damage, the boat retains the property of self-healing when capsizing.

The strength of the hull ensures the safe launch of the boat into the water with a full number of people and supplies. When testing boats with a full load (people were replaced with appropriate ballast) they were dropped into the water from a height of 3 m. The strength of the hull was also tested for impact with the side against the wall, and the speed of the boat at the moment of impact was 3.5 m / s.

To improve detection at sea, the entire outer surface of the boat is painted orange.

The seaworthiness of the boat has been tested in natural conditions. It is recognized that it can be used to rescue the crew and passengers of emergency ships in any area of the oceans.

By the time the requirements of the new chapter III of the SOLAS-74 Convention come into force, the domestic shipbuilding industry has prepared five new types of lifeboats for mass production, including special boats for tankers.

In port cities, among the pleasure and tourist amateur ships, you can always see a lot of boats, and even yachts, converted from ship boats that have served their time. Most of them hung on davits for ten or fifteen years; they were warmed by the tropical sun, covered with an ice crust in the northern seas, thrown by a wave against the side of the ship, poured with showers, and now the stern inspector of the Naval Register finds defects during the next survey of life-saving appliances, the boat can no longer be considered absolutely reliable.

But the crew of the ship in the event of an accident will be forced to trust her with their lives! And this can happen in the most difficult conditions - in a stormy sea, far from the coast, or vice versa - on a cruel breaking wave. There are doubts about the reliability - it means that the naval service is over! (and many boats are generally “written off” ashore only because they are being replaced with more advanced ones - plastic, motor ones.)

In a calm environment - on a river or in a bay - the same old boat, turned into a pleasure craft by an amateur, can still serve for many years. The new owner of the lifeboat may leisurely make repairs that are not permitted or deemed unreasonable for the ship's life-saving appliances. For example, to eliminate the water leakage of the dried skin by pasting the body with fiberglass; change worn trim belts; install duplicate frames next to the cracked ones.

It's worth the work! After all, having repaired a decommissioned boat, an amateur shipbuilder receives a obviously seaworthy and durable hull with a large internal volume, which can be rationally used to equip a comfortable cabin and all the necessary premises of a displacement pleasure-tourist vessel.

It will take much less materials to purchase than when building a new ship. All work can be done outdoors - under any cover or canopy, and most importantly - work on the interior fit-out no longer requires such a high qualification of the performer as the construction of the building itself. However, it would be a mistake to think that a person who, on his own, converts a boat into a boat (or, moreover, a yacht) does not encounter difficulties.

There are many. They are explained by the specific purpose of the lifeboat, which should, first of all, accommodate as many people as possible in case of an accident (this is not up to convenience!) And give them the opportunity to hold out until the rescuers approach (it is not required to develop high speed!).

Now you have to remove the transverse and longitudinal banks, air boxes; close the bow with a deck and mount the wheelhouse; take care of ensuring sufficient draft and deepening of the propeller with a relatively small load that a pleasure boat will have; it is not uncommon for the hobbyist to adapt a purely rowboat to fit the engine and fuel tanks.

The number of design problems increases dramatically if you want to get a motor-sailing vessel: it is far from easy to ensure stability and good controllability when sailing, to achieve a decrease in drift on sharp courses. How are these problems solved by amateur shipbuilders? This is the subject of our next review.

0 conversion of old boats into yachts was reported in the 30th edition of the collection (“Asmodeus” from a 6.7-meter boat and “Au-ra” from a 7.8-meter work boat), 9th edition (a yacht from a 10-meter longboat), 3rd issue (a yacht from a 6.1-meter yal-"six"). Two options for converting the "six" into a boat and a motor-sailing vessel are considered in the 5th issue. Articles will also be useful: “A boat must be beautiful” (issue No. 7), “Motor-sailing yachts” (issue No. 9), “Slow boats” (issue No. 18) and other materials.

Former naval boats (yawls) also quite often begin a second life, falling into the hands of amateur shipbuilders. In 1969, the Irkutsk Marine Club DOSAAF handed over to M. A. Zubovich for restoration the YAL-6, produced in 1955.

Old rusty patches and remove a thick layer of putty and paint accumulated over many years of operation (no scraping helped, the paint was annealed with a blowtorch). The entire outer surface of the body was sanded, and then pasted over with fiberglass in three layers.

In the felling area, three frames with a section of 50 X 60 were additionally installed in the boat hull at a distance of a meter from one another. The upper ends of the top-timbers protruded 450, 375 and 300 mm above the fender, thus forming the basis for the installation of longitudinal coamings of the cabin.

The felling beams are cut into a spike on the protruding ends of the frames and fixed with bakelized plywood brackets on galvanized screws. Beams and frames under mast standers are reinforced. M.A. Zubovich removed the second and third banks, which were within the cabin.

In a cabin with dimensions of 1.8 × 2.0 m, he installed two locker-seats, between which there is a passage with a width of 350 mm in the bow and 550 mm in the stern. The floor covering the hold in this passage rises to the level of the seat at night and a solid couch is obtained, on which its entire crew of four can freely fit across the boat.

A stationary engine "L-12" is installed on the foundation of wooden beams, the long-term operation of which on many low-speed boats has created a stable reputation for reliability and economy. Outboard water is supplied to the cooling system by pressure from the injection surfaces of the propeller blades. Hot water, before being thrown overboard, is passed through a radiator that heats the cabin in the autumn.

The engine is closed on top with two hinged covers, which serve as the aft deck. The engine shaft is connected to the propeller shaft through the lift cardan from the ZIL-585 dump truck. The shaft is brought out beyond the transom 275 mm above the keel line. The screw is protected from below by a spur (ski) made of a steel channel; the steering wheel bearing is fixed on it. Thanks to this, both the propeller and the rudder remain intact when the ship is grounded.

A generator with a relay-regulator from a Moskvich car is mounted on the engine, powered by a 12 V battery. The device allows you to power the lighting system and navigation lights, a receiver and a tape recorder. (The generator was installed according to the drawings and materials given in No. 9 of the collection.)

The bow compartment - from the stem to the first can, is closed by a sealed bulkhead and is used to store sails. The mast is placed on a metal stand on the roof of the cabin. The standard armament of the yawl has been replaced by more efficient armament from the Flying Dutchman class dinghy, however, when tacking under sail, the boat has a strong drift, since the area of lateral resistance of the underwater part is insufficient.

Since the "Wind Rose" is a motor-sailing vessel, such a disadvantage, according to M. A. Zubovich, can be put up with. The ship goes well in the backstay and jibe. Considering that the vessel is used for navigation on Lake Baikal, where it is sometimes very difficult to find fuel, the possibility of using sails on the same passing courses already seems to be a considerable advantage - it allows you to save gasoline, and sometimes just take a break from engine noise.

Here is what M. A. Zubovnch says about his first trip to the Wind Rose:

“It was back in 1968. We went out into the lake in calm weather, leading the Kazanka in tow, loaded with fuel and other equipment. The crew consisted of four people. With all this, the average speed under the engine was about 7 knots, which suited us perfectly.

In long-distance hiking trips, the main thing is reliability and safety! Two hours later, a light southeast wind blew - a kultuk. The wind picked up quickly. They set the sails and turned off the engine - the boat was heading north at a speed of about 5 knots. Ten hours later we were on the way to Peschanaya Bay.

At the crossing, we had to use a patent reef, reducing the area of the grotto, since we were heeling heavily during gusts of wind. The ship, even when heeled, did not take on water. We passed the next stage to the Olkhon Gates under the motor: we could afford such a “luxury”, since there is a gas station in the village.

Having stocked up with gasoline there, they headed for Nizhne-Angarsk. A distance of 600 km was covered in six days. And in total, about 2000 km were covered during the first voyage. In order to save fuel, the slightest possibility of sailing was used. In the course of many years of operation, the Wind Rose has shown excellent seaworthiness.

The use of a sailing rig in combination with a motor allows for very interesting voyages over long distances.” M. A. Zubovich used highly efficient sailing equipment from a modern racing dinghy, but, of course, it was not possible to realize the high qualities of Bermuda sails on a ship that was not equipped with any devices to counteract lateral drift - drift.

Moreover, the high windage with armaments of this type also led to the appearance of a large roll when the wind increased. (It can be noted that as a result of the alterations, the stability of the boat has deteriorated: the deck in the bow, the design of the wheelhouse, the gas tank of a solid capacity are located high and accordingly increased the center of gravity of the vessel.)

Therefore, for such cases of using sails as an auxiliary means - mainly in fair winds - more convenient armament with latin, gaff or guari sails is strongly recommended. These sails have a lower center of wind pressure than Bermuda sails of equal area; accordingly, the ship will list less in a fresh wind.

The advantages of hafel and rake weapons are also a lighter spars and a lower mast height; this not only simplifies the manufacture of the mast, but is also important when sailing on inland waterways, when you have to pass under numerous bridges and power lines.

Generally speaking, on motor-sailing. ships sailing mainly along rivers can be content with an even simpler type of weaponry - with a straight sail briefcase. All the same, sailing against the wind and current is tedious, and sometimes simply impossible; on fair winds, a brief is also good.

The direct sail device is quite well known. Ray is lifted by a halyard fixed to its middle with the help of a rax-yoke sliding along the mast. To set the sail at the right angle to the center plane of the vessel, braces are used, drawn from the cockpit to the ends - the legs - of the yard, and sheets, which, for ease of sail control, are best carried out, as shown in the sketch.

In its middle, the sheet is attached to the lower corner of the sail, one end (it is, strictly speaking, a tack) is passed through a guide shoe or block located at the side in front (about 0.5-0.7 m) of the mast, the other end (actually sheet) - through the same butt behind the mast. From the windward side, the “tack” wraps around the front side luff of the sail, and from the leeward side, the “sheet” is selected so that the sail does not rinse with the wind.

The shrouds with such armament should be sufficiently carried aft so that they do not interfere with the turn of the yard and more reliably unfasten the mast from behind. Along the way, a few recommendations for choosing the size of the brief. The mast is usually made with a height (from the deck or deckhouse roof) approximately equal to half the length of the boat. The width of the sail along the luff is taken equal to the width of the vessel, and the upper (along the yard) may be somewhat larger.

On the "Windrose" quite a lot of space is occupied by the "engine room" - the engine is installed far from the sternpost. It would be possible to move it a little aft and gain additional cockpit area if the author applied a different foundation design.

An original solution is offered by E. K. Likhushin (from Kuibyshev), who also used the body of the old "six". Since it is very narrow in the stern itself, it turned out to be impossible to install the engine on the longitudinal sub-engine bars in the usual way. E. K. Likhushin fixed these bars to the frames not lower, as usual, but above the engine paws in a plane parallel to the waterline.

The horizontal angle between the bars was about 30°, and the space between them was sufficient to accommodate the engine. The engine paws are supported on two welded trapezoidal brackets (made of steel squares) fixed on the longitudinal bars.

The aft seat had to be lengthened forward by 150 mm; for servicing the motor, a hatch is cut in it, closed by a lid; here, under the seat, there is also a gas tank. E. K. Likhushin retained the standard rudder blade. It was necessary to cut it (as well as the stern beam) to accommodate the screw quite a bit. This was possible thanks to the displacement of the steering pins from the stem.

As a good example of solving the issues of architecture and interior layout of yachts equipped from lifeboats, one can name a 5.5-meter yacht built by Leningrader M. N. Bogdanov (general drawings were developed by A. B. Karpov). The sides of the boat are built on with a wide belt made of bakelized plywood: at the stem the width of this belt is 300 mm, in the stern - 360 mm. The upper part of the cabin is designed as a forecastle - a superstructure that extends from side to side along the entire width of the hull.

The side walls of the superstructure are installed with an inclination of 8-10 ° inward; at the extremities they are vertical and are attached to the bars with which the stems are built up. The result was a spacious, wide cabin with a sufficient clear height (1.3 m) with a slender silhouette of the yacht. Aesthetic perception is subject to the coloring of the superstructure in a dark color, which differs from the color of the side; a powerful oak collar also separates these surfaces, visually reducing the overall height.

Another advantage of the variant with a forecastle is a spacious, comfortable deck for work and rest. The mast step is supported by a semi-bulkhead dividing the internal volume into two rooms - two cabins. The bow cabin has a wide double sofa, and wardrobes are located to the side of it on the starboard side. The cover of the forluka (its size is 500×400 mm) is made of thick Plexiglas.

In the layout of the aft cabin, the designer also departed from the traditional symmetrical arrangement of sofas. On many lifeboats, the keelson, which is laid in the DP on top of the frames, protrudes above them and above the payolas to a height of up to 100 mm and, with a symmetrical layout, is underfoot; usually the height of the cabin because of this has to be further increased.

In this case, the keelson does not create any inconvenience, since it turned out to be on the side of the main passage. The table on the left side can be lowered to the level of the seats to form a one-and-a-half place. The cockpit is self-draining (since its bottom is only 200 mm above the waterline, the drain scuppers must be fitted with non-return valves, such as float type).

The engine is installed in the afterpeak separated by a watertight bulkhead and is serviced through a hatch in the deck. An interesting variant of converting a 7-meter lifeboat into a sailing-motor yacht was performed by A. Tabachnik from Leningrad.

All air boxes and cans were removed from the hull, sensible things and the gunwale were removed. After cleaning from the old paint, defects were found in the sheathing, made from strips of bakelized plywood. The sheet piling belt suffered the most - the groove along the keel leaked heavily. However, they did not begin to replace this belt, and the groove was sealed by putting here an overhead triangular rail on canvas and oil putty (see sketch).

The damaged areas of the skin on the stems were covered with overlays of 1-2 mm brass. The places repaired in this way did not let water through at all. The future yacht was supposed to sail in Ladoga and Onega lakes, known for their stormy nature, so the need to install a heavy false keel and equipment for a self-draining cockpit did not raise doubts among the participants in the construction of the vessel.

To attach a 500-kilogram false keel, 60 mm thick pine floors were installed on the bottom, and powerful keel bolts were passed through five of them. The floors are cut into keel and sheathing, and a regular keelson is laid on top of them. The engine foundation is a welded structure consisting of two steel floors connected by longitudinal beams made of 45X45X5 square.

The height inside the cabin was chosen as minimal - 1450 mm from the floorboard. Due to this, the cabin turned out to be low, in good harmony with the hull and not adversely affecting the seaworthiness of the vessel. They decided to arm the yacht with a two-masted Bermuda schooner. This made it possible to obtain a significant total sail area (about 30 m 2) with a relatively low position of the sail center.

In addition, the distribution of windage on two masts allows you to use different options for carrying sails, depending on the specific sailing conditions and improve the agility of the vessel: after all, boats with their long keel are “not very willing” to make turns, especially in strong winds.

However, these fundamentally correct calculations of the builder in this case were not fully justified. Under full sail, the ship is strongly driven; Bermuda sails of a small area work inefficiently on it (in particular, due to harmful mutual influence). In the future, it was decided to re-equip the yacht with an ordinary sloop with a large genoa.

In the very first trip along the restless Ladoga, the ship demonstrated high stability. It has a two-cylinder water-cooled gasoline engine that develops 20 hp. with. at 3000 rpm. In order to do without a reversible clutch to ensure reverse and idling, the yacht builders manufactured a three-blade adjustable-pitch propeller (using the drawings of A.P. Shirshov, published in the 10th edition of the collection).

The speed under the motor was 7 knots. The dimensions of the engine room did not allow using the handle to start the engine, so I had to put a starter from the Moskvich-408 car, and replace the flywheel with another - with a ring gear (from the Zaporozhets engines). The battery is charged from a 300-watt generator from the GAZ-21 engine.

Water is supplied to the cooling system by a two-section pump, the design of which uses impellers from the Moskva-25 outboard motor. From this same The engine also has a fuel pump. The fuel supply is stored in two regular air boxes of the boat with a total capacity of 80 liters.

Naturally, with an increase in the size of the boat, there are more opportunities to make the future boat or yacht more comfortable, it is better to adapt them to long-distance voyages. For example, in the project for the conversion of a 10-meter rowboat into a motor-sailing yacht, carried out by D. A. Kurbatov, it is planned to increase the side height to 1.6 m and equip two cabins with a height in the rooms of 1.9 m and 1.7 m, with six beds.

Four-cylinder diesel engine "4CHSP8.5/11" with a capacity of 23 liters. with. gives the yacht a speed of 6.5 knots. It is installed in the very stern, under the cockpit, and is closed by the hood. The helmsman's post is protected by a cabin open from the stern, which also serves as an entrance vestibule. Two fuel tanks located under the cockpit platform have a total capacity of 360 liters and provide an engine cruising range of 450 miles.

The galley is located directly at the entrance, thanks to which the room is well ventilated when a similar hatch is open; the amplitude of pitching in the middle part of the vessel is small - this contributes to the successful operation of the cook at sea. The forepeak is used as a sail storage and sleeping quarters for three crew members.

The forluk with a porthole built into it has an enlarged size for the convenience of working with sails. The wardroom, in addition to the portholes in the cabin coamings, is illuminated (and ventilated) through the upper light hatch. The yacht is designed for combined navigation with access from inland waters to the sea, therefore, the vessel is equipped with a gaff tender with a retractable topmast.

By changing the sails on the tender, you can effortlessly "follow" the changes in the wind and vary the sail area over a very wide range. With a fresh wind at sea, the yacht will be able to sail only under the working staysail and mainsail (total area 41.5 m 2), having the position of the center of sail 600 mm forward of the center of lateral resistance.

The jib increases the total windage by 12 m 2; the ship will also be able to sail steeply into the wind. Topsail increases the total sail area to 61.5 m, but this option is of course only acceptable in light winds (it can be very useful when sailing in conditions where it is important to use a top wind).

This vessel will not be a good tacker: this would require a more efficient and deep keel, unsuitable for the given navigation conditions (draft is limited) and, in addition, much worse driving performance under the engine. A compromise option is proposed with a 500 mm high false fin, made, as usual, in the form of a welded steel box filled with scrap metal and cement; this false keel is attached to reinforced floors through the keel with M18 - M20 bolts.

Its weight is 1200 kg, and the total displacement of the yacht is about 5 tons with a draft of 1.4 m. will be convenient, for example, when setting up a jib or mooring to a high wall.